Innovative Products and Solutions

Sustainable Development Goals:

SOLUTIONS FOR FAST-GROWING TECHNOLOGIES

IDEX is rising to the challenge of developing fast-growing technologies in sectors like life sciences, intelligent water, space technologies, high-performance semiconductor fabrication and metrology, fire and rescue technologies, and transitional energy innovations.

Through our diverse portfolio of companies, IDEX makes products that contribute to health and safety and have a positive social impact. We also partner with our customers to help them reduce water and energy usage and drive efficiencies. The following product highlights are just a few examples of the many ways in which we harness the collective power of great teams to innovate quickly and deliver trusted solutions.

Related Stories

IDEX Health & Science (IH&S) is advancing the field of spatial biology, a cutting-edge technique essential for understanding biology at a deeper level, uncovering the mechanisms behind diseases, and developing effective treatments.

Spatial biology allows researchers to look deep into the molecular interactions within a biological system by pinpointing the location of molecular activity in two-and three-dimensional space. The technique requires advanced methods for resolving chemical signatures within a cell or tissue, and is critical for fully understanding how biology works, including the mechanisms behind disease and the development of treatments.

IH&S simplifies this complex field by creating advanced optics and fluidics technologies that make multidimensional analysis more accessible to scientists. By partnering with instrument manufacturers, IH&S helps design the next generation of tools that enable researchers to perform precise chemical and molecular analyses. These innovations are driving progress in spatial biology, empowering scientists to explore biological systems with unprecedented clarity and efficiency.

Our Mott business is tuning its highly sophisticated filtration solutions in numerous ways in response to a global transition to clean energy.

The team is developing cutting edge solutions in the green hydrogen space. In this emerging field, Mott is accelerating development of its porous transport layers (PTLs), a critical component in the production of hydrogen from water, with support from a $10 million grant from the U.S. Department of Energy. In partnership with Nel Hydrogen, Forge Nano, Inc., and the University of Connecticut, this initiative aligns with the federal “Hydrogen Shot” goal to reduce the cost of clean hydrogen to $2 per kilogram by 2030. This development work is essential to scaling large electrolyzers capable of providing enough clean hydrogen per day to power 10,000 homes or 2,000 vehicles.

In addition to these breakthrough technologies, Mott has recognized other ways in which more traditional industries may be changing. Because global oil demand could decrease in response to a clean energy transition, some traditional oil refiners have begun pivoting to the production of petrochemicals. In the oil and gas industry, Mott is providing critical filtration technology for a groundbreaking project in South Korea, in collaboration with another engineering partner. This major initiative strengthens Mott’s position as a trusted partner in global chemical production and high-purity process applications. The project will produce key chemical building blocks like ethylene, one of the most widely used compounds in the world, enabling the production of everything from plastics to textiles. Mott’s filtration systems are designed to remove fine particulates from feed streams in chemical conversion processes for the purpose of enhancing system reliability and product purity.

These are just a few of the ways in which Mott’s agile team is leveraging its core technology across multiple applications in response to a changing world.

Our businesses have developed a variety of technologies critical for space exploration and global advancement of satellite communications.

Custom optical components and shutters for imaging and detection, created by Advanced Thin Films, Iridian Spectral Technologies, and CVI Laser Optics, are applied to telescopes, satellites, drones, and environmental instruments.

Our solutions offer optimal performance in various applications, including satellite-based Earth observation and LiDAR scanning, remote imaging, environmental services, infrastructure monitoring, disaster management, agriculture, and energy monitoring.

The growing ability to communicate from anywhere on Earth through satellite technologies is possible through our precise lasercomm solutions designed to withstand the rigors of prolonged space travel.

In addition, our Mott filtration and flow control products make possible advanced space propulsion technologies, life support mechanisms, and energy storage systems. Mott’s flow restrictors ensure a laminar flow, crucial for accurate instrumentation readings and optimal satellite thrust. The company’s spacecraft propulsion filter products help propellant or water-cooling systems operate without particle contamination.

Our digital world is advancing at incredible pace, made possible by ever-smaller scaling of the

silicon transistor. Today’s leading AI GPU (graphical processing unit) has over 200 billion transistors on a single chip. 144 million of those transistors fit in an area the size of the head of a pin.

Fabricating these atomic scale features requires precision and stability. During lithography, the process where intricate patterns are precisely transferred onto a silicon wafer using light, a temperature change within the machine of just one thousandth of a degree Celsius can create a misalignment of dye patterning and cause failures in the wafer.

Millux, an IDEX materials science business, uses micro-precision laser machining to fabricate components for lithography machines with intricate flow paths which allow exacting thermal and dimensional control.

Intense storm events are increasing demands on stormwater management and wastewater collection systems, many of which are aging and in need of repairs.

Municipal wastewater management agencies and other customers are attempting to prioritize their investments and reduce the risk of catastrophic system failures, like overflows that harm the environment and lead to property damage and health and safety issues. IDEX Intelligent Water businesses combine to deliver actionable insights about infrastructure asset condition and performance to collection system operators, which enables them to make better decisions, meet ratepayer expectations, improve operating efficiencies, and comply with regulatory requirements.

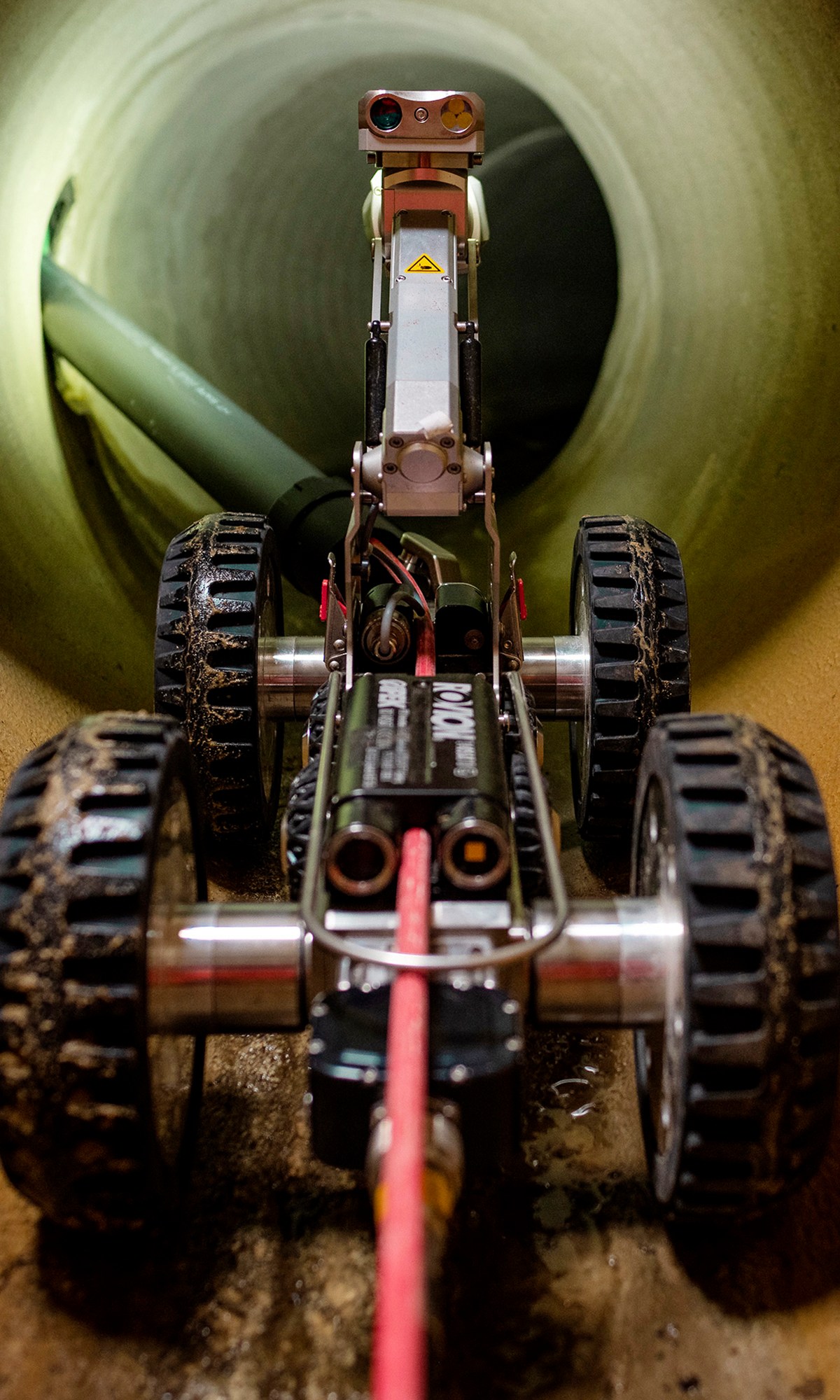

We provide sewer condition inspection and performance monitoring utilizing robust inspection tools, such as tethered robotic crawlers produced by iPEK and Envirosight, and flow monitoring devices, software, and services from ADS. We continued to expand our capabilities with the 2024 acquisition of Subterra AI, enabling inspection and sewer system data collection using rapid, untethered, free-floating solutions.

Subterra Sewer Scouts float down the channel, screening for potential defects, in order to maintain optimal performance and prioritize maintenance and rehabilitation efforts. The system can quickly access hard-to-reach sections of sewer networks, including large interceptor pipes that are less frequently inspected.

Using advanced software, computer vision, and AI, the captured video footage actively geolocates cracks, root penetrations, and other potential issues for the operator to easily see on screen. Armed with this information, agencies can better plan repairs of small problems before an overflow causes damage to property and the environment.

IDEX Fire & Safety businesses empower first responders to save lives in critical moments. Hale Products, Akron Brass, Godiva, LUKAS, and Hurst Jaws of Life manufacture essential equipment for emergency responders, specializing in firefighting pumps, controls, and hydraulic rescue tools.

The safety of our products’ users is a top priority, especially when those users are first responders. Our IDEX Fire & Safety businesses are leading innovation with the automated SAM Waterflow System, which digitally manages water pressure and flow during firefighting operations, while enhancing firefighter safety and operational efficiency.

Firefighter Jason Cerrano developed SAM after seeing an opportunity to improve the efficiency and safety of pump operations on the fireground. He started his career in the fire service as a volunteer while attending college for mechanical engineering. After graduating, he decided to pursue a fulltime career in the fire service in the St. Louis area.

During that time, he developed the concept for an automated fire pump with remote capabilities to allow the operator to move around the scene and work with the crew. The concept became a reality as part of the IDEX Fire & Safety suite of solutions.

Traditional firefighting equipment requires manual adjustments to water pressure and flow, exposing firefighters to critical safety risks such as overpressure and underperformance. The SAM Waterflow System integrates real-time sensors and automated controls that precisely adjust water flow to optimal levels. This reduces risks to firefighters and enhances fire suppression efficiency.

IDEX systems are designed for ease of use, enabling firefighters to focus on critical tasks rather than technical adjustments. By combining cutting-edge innovation with a deep understanding of firefighting challenges, IDEX is setting a new standard in emergency response automation.

Flow Management Devices (FMD) has developed the first known small volume prover specifically designed for carbon dioxide (CO2) flow meter calibration. This innovative design combines high-pressure capabilities and a wide temperature tolerance to enable accurate calibration under the challenging conditions required for CO2 transport and injection processes.

CO2 transport is critical for carbon capture, utilization, and storage, a key technology in reducing global greenhouse gas emissions. By safely moving captured CO2 to storage or utilization sites, the transport infrastructure supports large-scale efforts to mitigate climate change. Accurate flow measurement is essential to ensuring the efficiency and safety of these operations, and the FMD prover plays a vital role in achieving this.

Sanku, a leading charity in the fight against malnutrition across Africa, focuses on enhancing the nutritional quality of staple foods through innovative fortification equipment and capacity-building initiatives for local millers.

Our team at Matcon collaborated with Sanku to refine a system that enables the safe and efficient formulation, blending, and packaging of fortified products. This commercial partnership supports Sanku’s mission to scale hygiene-focused, scalable solutions, helping the organization reach 15.8 million people in 2024 with nutrient-rich flour.

In 2024, Sanku opened the Nutrient Premix Factory in Tanzania, with Matcon’s cutting-edge blending equipment as part of the production process. As the first facility of its kind in Eastern Africa, the factory produces high-quality, affordable premix not only for Tanzania but also for millers in Kenya and Ethiopia. Looking ahead, Sanku aims to replicate this success across other parts of Africa, expanding its reach and delivering life-changing nutritional solutions to millions more in need.

Warren Rupp’s Cognito Electric Operated Double Diaphragm (EODD) pump, launched in 2023, delivers a 75% reduction in electricity consumption compared to similar air operated pumps. Used in a wide variety of applications to transfer challenging liquids, the IoT-enabled Cognito’s electric motor with a reduction gearbox has moved the needle on expectations for energy efficiency in the market.

Our team at Toptech is playing a critical role in helping the airline industry meet its emissions goals by supporting the expansion of Sustainable Aviation Fuel (SAF) infrastructure. SAF blends traditional jet fuel with bio-fuel alternatives that emit less carbon. Toptech helps automate the delivery of sustainable feedstocks to SAF production facilities, streamlining the process and enhancing efficiency. To help meet growing demand, our technology keeps the plant up-and-running, to help maximize the production of SAF.

The food service industry has traditionally relied on CO2 to power pneumatic beverage pumps in fountain beverage systems at restaurants around the world. These pumps transport syrup from the back of a store to front lobby dispensers or drive-through stations. However, as these pumps consume CO2, the gas is vented into the atmosphere, contributing to carbon emissions.

Our Gast pneumatics business developed an innovative range of compressed air systems to replace CO2 for driving these beverage pumps. While CO2 is still needed to carbonate beverages, splitting the demand by using compressed air for pump operations can reduce CO2 usage by 40% or more. This solution significantly eliminates the direct release of CO2 into the environment, offering a more sustainable and environmentally-friendly option for the food service industry.

ABEL Pump continues to improve the efficiency of its pumps, including through its “Smart Pump Assistant” AI tool. ABEL piston diaphragm pumps are integrated with AI technology that allows the pumps’ sensors to “talk,” enabling the operations team to easily understand what the pump needs to perform at peak efficiency.

With predictive analytics honed through more than 170,000 hours of pump running time, Smart Pump Assistant provides insights into a pump’s conditions and allows for immediate detection of any anomalies requiring corrective actions. Thanks to the intelligent systems, maintenance cycles are extended by up to 50% and the use of spare parts can be reduced by up to 25%, significantly reducing the consumption of resources.

Developed by our Fluid Management business, our automatic paint dispensers have revolutionized paint tinting by eliminating manual purging, including at paint departments in large home improvement stores around the world. These dispensers are estimated to prevent nearly 700,000 liters of paint colorant waste annually. In 2024, we expanded this technology to entry level dispensers, projected to save an additional 250,000 liters of waste each year.

Additionally, to meet growing demand for biocide free colorants, which are more eco-friendly but also prone to bacterial and mold contamination, the Fluid Management team developed two innovative solutions using controlled disinfectant spraying and UVC lighting solutions to eliminate contaminants and support colorant longevity.

One of North America’s largest manufacturers of solid-oxide fuel cells, which create electricity without traditional combustion, uses Airtech Vacuum high-speed blowers in their critical systems.

Airtech engineers worked in close partnership with the company, growing with them as they now produce the highest efficiency solid-oxide fuel cells commercially available worldwide.

Demand for these fuel cells continues to grow, providing everything from electricity for big box retail stores and server farms to supplemental power on ships. The sixth-generation Airtech blowers are market leaders in efficiency, requiring only five percent of the total power fuel cell module output, compared with 21% of the first generation module.

Airtech specializes in low pressure compressors, particularly for high temperature and corrosive gas mixtures. It is part of the IDEX Performance Pneumatics platform, which also includes Gast and US Valve.

Airtech Vacuum is supporting a multinational fuel cell manufacturer dedicated to decarbonizing global rail systems. This manufacturer provides proven zero-emission alternatives to traditional diesel combustion engines, with its fuel cell stacks powering the first fleet of hydrogen-powered trains.

The manufacturer approached Airtech with a need for a robust and reliable anode recirculation compressor to recirculate unused hydrogen in Proton Exchange Membrane (PEM) fuel cells. Airtech’s engineering team collaborated closely with the customer’s engineers to fully understand the application requirements and challenges. Within seven months, Airtech delivered its first working prototypes for first-article testing.

Through its clean water subsidiary, Mott is revolutionizing how farms manage agricultural waste, using digesters with advanced filtration systems to transform manure, digestate, and farm runoff into clean water and concentrated fertilizers, driving both environmental sustainability and operational efficiency.

Currently, Mott’s technology can process up to 100,000 gallons of manure daily, turning it into clean water that could fill 150 backyard swimming pools. The concentrated nutrients produced during the process can fertilize hundreds of acres of farmland naturally, significantly reducing reliance on synthetic fertilizers.

Mott’s digester systems are enabling farmers to transition into regenerative methods of production. These compact, modular solutions are designed to fit farms of any size, enabling advanced waste management without requiring additional land. By helping farms conserve water, reduce waste, and improve agricultural productivity, Mott is contributing to a healthier planet and a more sustainable future for farming.

Technology is increasingly helping farmers apply herbicides and fungicides more selectively in ways that help reduce the amount of spray used, improving environmental impacts and reducing costs to farmers.

Banjo and KZValve, which make agricultural pumps and valves for most leading manufacturers of large agricultural equipment, supply components for a variety of innovative new solutions. Some systems use camera technology to detect when an actuator should open one of our valves to spray at exactly the right time. One major American tractor manufacturer estimates that its target weed spraying system can reduce nonresidual herbicide by more than two thirds compared to conventional practices.